Our World Gone Nano

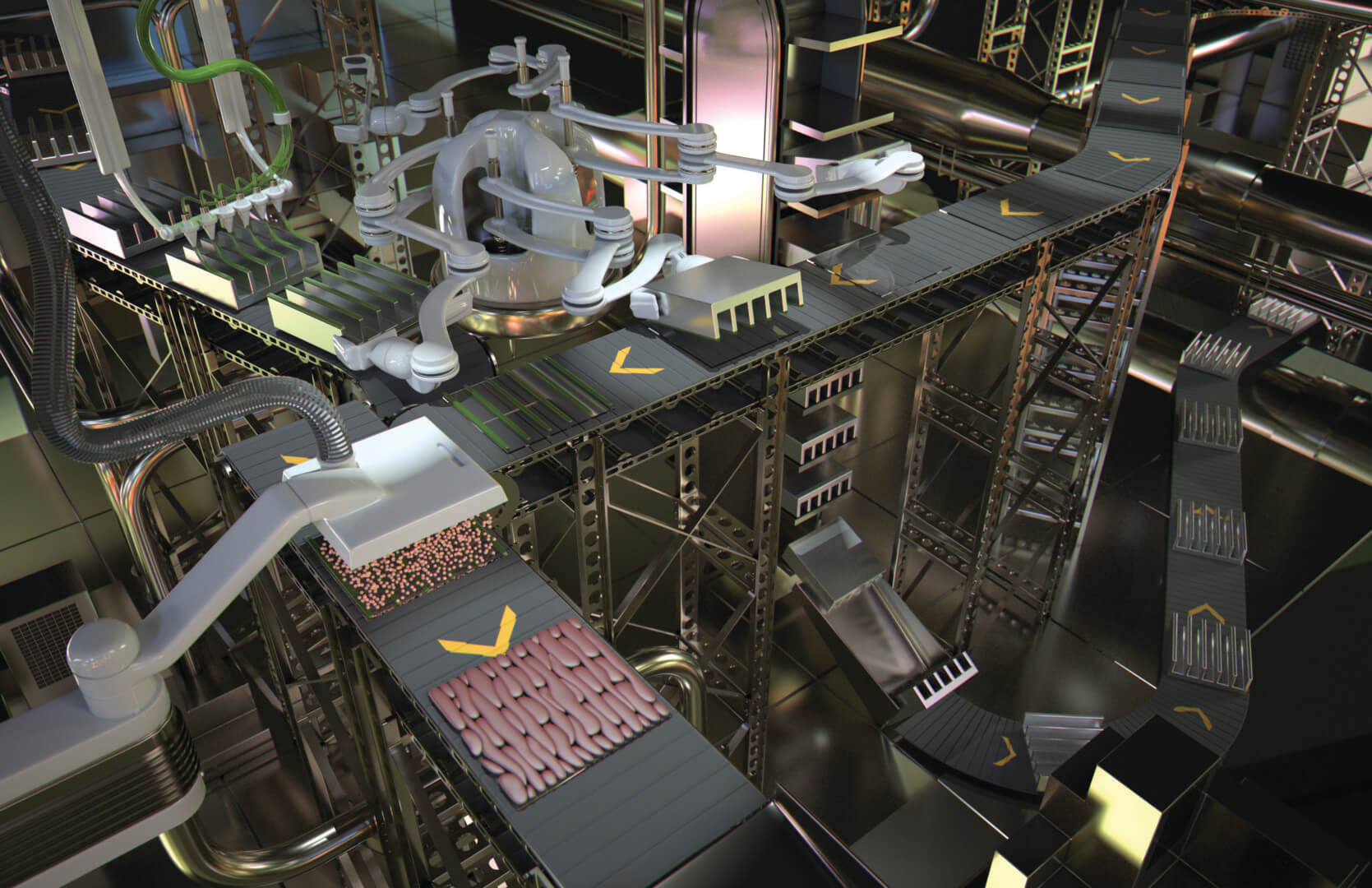

THE HEART FACTORY:

Assistant Professor Megan McCain hopes to re-create your heart on a chip, layer by layer. Here, micro-scale stamps created in the John O’Brien Nanofabrication Laboratory will be used to shape actual cardiac cells in neat, regimented rows that mimic the human heart.

The purpose: a tiny, future laboratory to test what heart disease drugs are best for you.

Illustration by Peter Bollinger

Thanks to advances in molecular engineering, nanotechnology is opening an entire unseen world to us. And many of those applications will be developed in the John D. O’Brien Nanofabrication Laboratory at USC.

Co-located in the USC Michelson Center for Convergent Bioscience with the Center for Electron Microscopy and Microanalysis, the Nanofab Lab will include all of the tools needed to build structures and devices the size of DNA or viruses. Both facilities will support the activities of not only the researchers at the Michelson Center, but also faculty from across the

USC campuses, enabling informal interactions that may inspire larger collaborative research efforts.

The lab is named for former USC Viterbi Executive Vice Dean John O’Brien, who shepherded the project from its conception through construction, but passed away in March 2017 before the Michelson Center opened last fall.

Andrea Armani, who oversees the operations of the lab, described it as a “machine shop for nanotechnologies.” Armani, the Ray Irani Chair in Engineering and Material Sciences at USC Viterbi, is one of 27 faculty members who plan to use the facility. By combining synthetic chemistry and nanofabrication, her group recently demonstrated a frequency comb made out of gold nanoparticles that can create a rainbow of light from a single color. Such high-precision light sources have numerous applications in fields like cybersecurity, GPS and the detection of toxic chemicals.

Ellis Meng, the Dwight C. and Hildagarde E. Baum Chair in Biomedical Engineering and Electrical Engineering-Electrophysics, is working with USC neuro-engineers to understand how memories are formed in the human brain. Her team is building a device made from flexible plastic that can be inserted into the brain to record its electrical activity. Printed on this device is a set of metal electrodes that record the electrical firing of individual brain cells using eight probes, each about the thickness of a single human hair. The devices are made using the same microtechnology that is used to create computer chips.

Megan McCain, assistant professor of biomedical engineering and the Chonette Early Career Chair at USC Viterbi, will engineer silicon wafers with custom micron-scale patterns, which she’ll use as templates to make stamps from a rubber-like material. These stamps pattern surfaces with proteins that cells will stick to — think of it as rubber ink stamping on a very small scale, McCain’s “ink” being cell-adhesive proteins, she explained. These surfaces are then used to grow heart and muscle cells. It’s a technique used to mimic the architecture of cells in healthy and diseased states, and informs her ongoing work to engineer human heart and muscle tissue “on a chip.”

Stephen Cronin, professor of electrical engineering/electrophysics, and his group are exploring new ways to convert heat waste into electricity. They will use the Nanofab Lab to make devices capable of measuring the thermoelectric voltages produced across atomic junctions between graphene and boron nitride. The thermoelectric voltage generated at this graphene/h-BN interface presents a new mechanism for improving thermoelectric energy conversion efficiencies. In the future, this will allow you to harvest wasted energy from, let’s say your oven, into electricity to power your TV.

This is just a small sample of the applications of nanometer-scale that will be advanced in the Nanofab Lab. This new nanotechnology-embedded world that will claim part of its origin story here at USC offers the promise of revolutionizing fields as diverse as building materials and clothing, food production, water and soil purification, medicine and computing, as well as the process of manufacturing itself.